O-ring

Products Category

Tag list

- 产品描述

-

Summary

The purpose of using O-ring seals is to prevent leakage and loss of liquids or gases (usually referred to as media). Due to its simple and convenient installation, as well as the small installation space required, O-ring is the most commonly used type of seal. As long as the design and material selection of the groove are correct and the working conditions are within the temperature range of the rubber material, the seal can achieve long-term sealing effect in static or dynamic sealing.

Describe

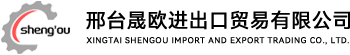

A O-ring is a circular ring typically made of elastic rubber (elastomer). Its size is determined by the inner diameter ID, outer diameter OD, and wire diameter W.

The O-ring should be precise and defect free, made of various types of synthetic rubber through hot injection or compression vulcanization (cross-linking).

Manufacturing process

There are two main production processes for O-ring elastomers.

● Compression Molding

(Compression molding=CM process)

● Injection molding

(Injection molding=IM process)When using CM technology for processing, the raw materials are manually added to the middle of the mold before the upper and lower molds are merged. Due to the time-consuming process, this technology is suitable for small batch and large-sized manufacturing.

Using IM technology, raw materials are automatically injected into multi cavity molds. This process is particularly suitable for large-scale and small-sized manufacturing.Characteristic

The O-ring is widely used in various sports and static sealing occasions due to its low manufacturing cost and usage method.

Standard

Most countries have established series product standards for O-ring, among which the American standard (AS568), Japanese standard (JISB2401), and international standard (ISO3601/1) are more commonly used.

Standard O-ring cross-sectional diameter W American Standard AS 568

British Standard BS15161.78 2.62 3.53 5.33 7.00 Japanese Standard JIS B2401 1.90 2.40 3.10 3.50 5.70 8.40 International standard ISO 3601/1

German standard DIN 3771/1

Chinese standard GB 3452.11.80 2.65 3.55 5.30 7.00 Priority metric size 1.0 1.5 2.0 2.5 3.0

3.5 4.0 4.5 5.0 5.5

6.0 7.0 8.0 10.0 12.0American Standard AS 568

(900 series)1.02 1.42 1.63 1.83 1.98

2.08 2.21 2.46 2.95 3.00Seal mechanism

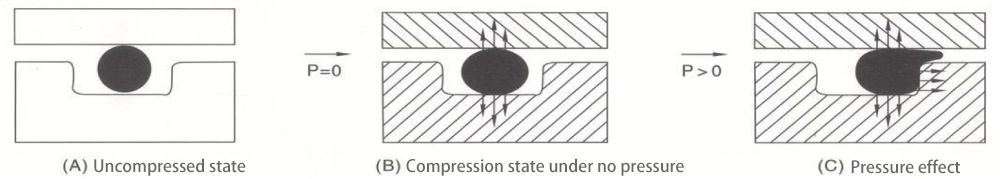

O-ring is an automatic bidirectional sealing component. The pre compression in the longitudinal and axial directions during installation endows the O-ring with its initial sealing ability. It increases with the increase of system pressure.

Static sealing Dynamic sealing Working pressure When there is no retaining ring, the maximum pressure can reach 2MPa

When there is a retaining ring, the maximum pressure can reach 40MPa

When using a special retaining ring, the maximum pressure can reach 200MPaWhen there is no retaining ring, the maximum pressure can reach 5MPa;

When there is a retaining ring, the pressure is higher.Movement speed The maximum reciprocating speed can reach 0.5m/s, and the maximum rotational speed can reach 2.0m/s.

General occasions: -30 ℃~+100 ℃; Special rubber: -60 ℃~+250 ℃; Rotating occasion: -30 ℃~+80 ℃

O-ring

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products